Research

At the Mechatronics Lab at Florida International University, our passion extends beyond revolutionizing structural health monitoring (SHM) with deep learning techniques; we are equally committed to designing and developing the next generation of machines. Our lab’s expertise encompasses a wide range of applications, from conventional to additively manufactured parts. We employ advanced sensing methods to not only ensure safety and optimize performance but also to innovate in the realm of machine design and development. Our dedication to innovation and cutting-edge research positions us at the forefront of industry advancements. Join us in exploring new possibilities and uncovering transformative insights in the dynamic field of mechatronics and SHM, where excellence meets exploration.

Structural Health Monitoring

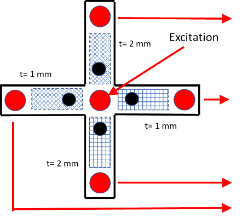

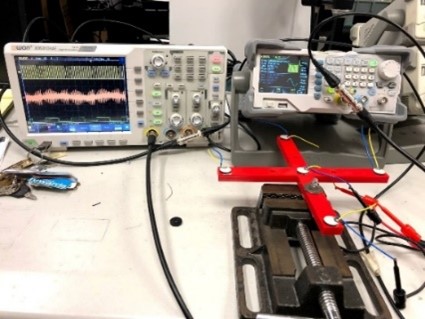

Explore the remarkable world of Structural Health Monitoring (SHM) at the Mechatronics Lab, where cutting-edge engineering meets excellence. At Florida International University, our dedicated team is committed to revolutionizing SHM by implementing deep learning techniques. Focused on the early detection and diagnosis of defects in structural components, our advanced sensing methods are pivotal in identifying potential issues before they escalate. This proactive approach to monitoring enables us to not only safeguard the integrity of structures but also contribute significantly to their longevity and reliability. With our unwavering focus on innovation and pioneering research, we strive to uncover new insights and drive progress in the industry. Join us on this transformative journey towards the future of structural health monitoring, exclusively at the Mechatronics Lab.

Design & Development

At the Mechatronics Lab, we’re actively involved in fostering innovative senior design projects, like the Autonomous Asphalt Laying machine. This project represents a significant leap in paving technology, which traditionally relies on large, diesel-powered machines and extensive labor. Our focus has been on revolutionizing this process to make it more efficient, environmentally friendly, and safer.

The design and development process in our lab has been pivotal in transforming these machines. We aim to create compact, smart, and autonomous asphalt layers powered by electricity, reducing environmental impact. Our approach involves using multiple smaller machines working in coordination, much like a swarm, to lay asphalt. This method allows for minimal road closures, enhancing efficiency and safety.

Key development areas include:

- Mechanical Design: Creating smaller, more maneuverable machines suitable for this innovative approach.

- Autonomous Driving: Leveraging lab resources to develop sophisticated control systems that enable these machines to operate autonomously and in coordination.

- Remote Operation: Designing systems that allow operators to control these machines remotely, eliminating the need for a physical presence in the work area.

This ambitious Autonomous Asphalt Laying machine project is just one example of the many diverse and innovative endeavors that pass through our lab, each pushing the boundaries of technology and engineering.

Facilities

Our Mechatronics Lab is equipped with state-of-the-art facilities, offering an extensive array of tools and equipment that, in conjunction with our student machine shop, provide a comprehensive environment for innovation and practical application. A part of our instrumentation is the Scanning Laser Vibrometer (Polytec PSV-400-B), a sophisticated device essential for precise vibration and modal analysis, enhancing our capabilities in dynamic testing and material characterization.

Alongside this advanced instrument, our lab boasts extensive 3D printing capabilities, enabling the creation of components in various materials, from polymers to metals. Our lineup includes high-end models like the Markforged Metal X, the 3D Systems Projet 2500-Plus, the Intamsys FUNMAT PRO 410, the Form Labs Form 2, and the QIDI TECH X-MAX, among others.

To complement our 3D printing arsenal, we also have a complete machine shop equipped with sophisticated CNC machine tools. This includes two Tormach 1100Ms and a Fadal VMC-15-XT, allowing for precise machining of metal components. Whether it’s for tensile strength testing, intricate metal machining, or detailed dynamic analysis, our lab’s facilities are designed to cater to a wide range of project requirements, from conceptual design to final product realization.

To complement our 3D printing arsenal, we have a complete machine shop equipped with sophisticated CNC machine tools. This includes two Tormach 1100Ms and a Fadal VMC-15-XT, which allow for precise machining of metal components. Whether it’s for tensile strength testing or intricate metal machining, our lab’s facilities are designed to cater to a wide range of project requirements, from conceptual design to final product realization.